Course Overview O v e r v i e w

- Course Overview

- Course Outline

- What’s Included

- What You’ll Learn

- Exam Details

Lean Six Sigma Yellow Belt Overview

Lean Six Sigma Yellow Belt is the entry-level certification that introduces professionals to the core principles of Lean and Six Sigma methodologies. It focuses on streamlining processes, reducing waste, and improving quality by using data-driven tools. This course equips learners with a foundation in continuous improvement and provides the skills to contribute meaningfully to process efficiency within their teams.

Being formally trained in Lean Six Sigma Yellow Belt enhances your ability to drive measurable improvements within an organisation. Certified professionals gain practical exposure to real-world tools and techniques, boosting their confidence in identifying inefficiencies and supporting improvement projects. With this knowledge, delegates can have a competitive edge in operational excellence.

At Training Deals, we make learning Lean Six Sigma flexible, cost-effective, and tailored for real-world success. Our expert-led training includes interactive modules, real-world examples, and flexible learning formats. Learners benefit from lifetime access to materials and ongoing tutor support. This makes Training Deals a trusted choice for building real-world Lean Six Sigma capability.

Lean Six Sigma Yellow Belt Outline

Module 1: Introduction to Lean 6 Sigma

What is Lean 6 Sigma?

Two Parts of Lean 6 Sigma

Focus of Lean

Lean Temple

Focus of Six Sigma

Making Customers Happy

How They Complement Each Other?

Key Principles of Lean 6 Sigma

Lean 6 Sigma Belts

TKA Lean 6 Sigma Belt Structure

Training Roadmap and Role of the Yellow Belt

L6S Support Network

Processes

Different Ways of Looking at Process Improvement

What is a Process?

Process Concepts

Types of Process

Comparing Process Types

Customers, Value, and Waste

What are Customers?

Who Wants the Outputs?

Tension Between the VOB and VOC

What Do We Mean by Value?

Path to Value

Dealing with Values

Muda (Waste)

Wastes (Muda) of Lean

Types of Demand

Case Study Exercise

Key Metrics

Module 2: DMAIC Cycle

What is DMAIC?

Define

Common Tools for Define Phase

Gemba Tools

Process Stapling

Measure

Common Tools for Measure Phase

Spaghetti (Movement/Transportation) Diagrams

Analyse

Common Tools for Analyse Phase

Improve

Common Tools for Improve Phase

Control

Common Tools for Control Phase

Module 3: Yellow Belt Tools and Techniques

Lean Triad

5s

Poka Yoke

SMED

Voice of the Customer (and CTQ’s)

Customer Chains

Steps of VOC

Affinity Diagrams

Kano Diagrams

CTQs and Requirements

SIPOC

What is a SIPOC?

CSandF Web Fulfilment SIPOC

Creating a SIPOC

Top Tips – SIPOC

Value Stream Analysis

Value Stream Terminology

Process Maps

Aim of Value Stream Mapping

Swim Lanes and Typical Process Map Contents

Value Stream Maps

Headache Tablets: Value Stream Mapping

Heijunka

Heijunka in a Nutshell

Single Piece Flow

Pull

Kanban

Three-Bin System

Andon

Variation and SPC

Statistical Process Control (SPC)

Two Types of Process Variation

Red Bead Experiment

Standard Deviation (SD) and Understanding Control Charts

Defects and Process Capability

Conversion Table

Process Capability

Identifying Process Efficiency

Key DPMO Terms

Identifying the Root Cause(s)

5 Whys

Fishbone Diagram

Solving Problems

Problem Solving Framework

Prioritisation Tools

Tools and Techniques to Generate Needed Solutions

Introduction to Kaizen

Kaizen in a Nutshell

Kaizen in a Business Setting

Lean Teams

Introduction to Lean Team

Managing Progress and Demonstrating Control

What’s included in this Lean Six Sigma Yellow Belt?

- Expert-led Training Sessions by Certified Instructors

- Course Completion Certificate

- Official Lean Six Sigma Yellow Belt Examination

- Digital Delegate Pack

What You’ll Learn in this Course

This course introduces you to the core principles of Lean and Six Sigma, providing practical tools to support process improvement initiatives. Each step of the journey builds your capability to identify inefficiencies and contribute to quality-driven outcomes.

Learn the fundamentals of Lean and Six Sigma methodologies

Learn how to identify and reduce waste in business processes

Learn to support DMAIC-based improvement projects

Learn to apply key tools like SIPOC, Fishbone, and 5 Whys

Learn to assist in data collection and basic process analysis

Learn how to contribute to a culture of continuous improvement

Lean Six Sigma Yellow Belt Exam Information

The Lean Six Sigma Yellow Belt exam evaluates your understanding of the fundamental concepts and tools used in Lean and Six Sigma methodologies. It focuses on process improvement, waste reduction, and the DMAIC framework. The details below outline the current exam structure.

Question Type: Multiple-choice

Total Questions: 40

Pass Mark: 70%

Duration: 1 Hour

- Type : Closed Book

Our Upcoming Batches

Mon 6 Apr 2026 - Tue 7 Apr 2026

Duration: 2 Days Coventry

Mon 13 Apr 2026 - Tue 14 Apr 2026

Duration: 2 Days Coventry

Mon 11 May 2026 - Tue 12 May 2026

Duration: 2 Days Coventry

Mon 1 Jun 2026 - Tue 2 Jun 2026

Duration: 2 Days Coventry

Request More Information

Corporate Training

Elevate your workforce with expert-led corporate training that enhances skills, boosts productivity, and aligns teams with your business goals.

Individuals Training

Unlock personal growth and sharpen professional skills with tailored training designed to build your confidence and career success.

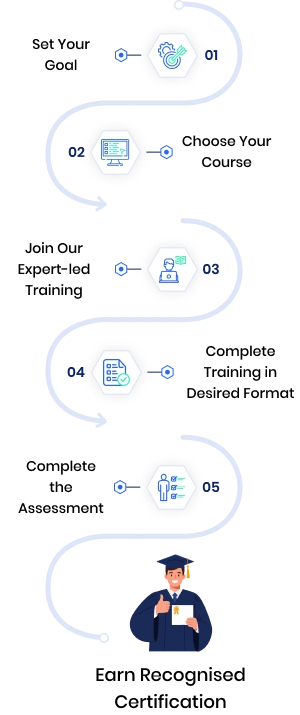

Your Path to Professional Recognition

Our path is designed to guide you through each stage with clarity, support and practical learning, helping you achieve your goals with confidence.

Step Forward with Globally Recognised Certification

A recognised certification is more than a credential. It’s proof of your commitment to professional excellence, providing you with the credibility, confidence, and global reach to advance your career in exciting new directions.

Globally Certified Professionals Over Time

Career Growth

81%Certified professionals reported receiving a promotion after earning their certification.

Global Opportunities

89%Certified professionals experienced access to new career opportunities, including leadership roles and global positions.

Not able to find what you are looking for

Our experts will guide you to the right course from thousands worldwide: tailored to your goals.

Frequently Asked Questions

Lean Six Sigma is a methodology combining Lean’s focus on waste reduction and Six Sigma’s data-driven approach to improve process efficiency, quality, and customer satisfaction across industries.

Lean focuses on eliminating waste and streamlining processes, while Six Sigma targets reducing variation and defects. Together, they create high-quality processes with minimal waste and errors.

A Yellow Belt is an entry-level Lean Six Sigma Certification, equipping professionals with basic Lean Six Sigma tools and supporting process improvement initiatives within teams or projects.

Yes, Lean Six Sigma is globally recognised across industries and valued by employers worldwide for process improvement, quality management, and operational excellence.

Lean Six Sigma principles are scalable and help small businesses reduce waste, streamline operations, improve quality, and maximise resources for better performance and growth.

What Our Customers Say About Us

Matthew Sullivan

HR Business Partner

Matthew Sullivan

HR Business Partner

Our HR team registered for the Change Management Foundation & Practitioner Training Course, and it couldn’t have been more valuable. The team gained practical frameworks to guide employees smoothly through transitions with confidence.

Olivia Barrett

Operations Manager

Olivia Barrett

Operations Manager

Our operations staff completed the Lean Six Sigma Green Belt Training Course, and it has been transformative. We can now identify inefficiencies quickly, and the tools we learned are already improving performance across the team.

Benjamin Foster

Product Manager

Benjamin Foster

Product Manager

Our product team took part in the Agile Project Management Foundation & Practitioner (AgilePM®) Training Course, and the difference is remarkable. We’re now more adaptive, collaborative, and efficient in managing change.

Lucy Harper

IT Support Lead

Lucy Harper

IT Support Lead

Our IT support unit attended the ITIL® 4 Foundation Training Course, and the results have been impressive. Processes are smoother, collaboration has improved, and the team finally speaks a common language of service management.

Edward Clarke

Programme Manager

Edward Clarke

Programme Manager

We joined the PMP® Certification Training Course as a leadership group, and it was outstanding. The trainer made every concept practical, and the exam preparation resources helped the whole team feel ready to tackle complex projects.

Amelia Rhodes

Project Officer

Amelia Rhodes

Project Officer

Our project office completed the PRINCE2® Foundation & Practitioner Training Course, and it has brought real clarity to how we manage projects. The trainer’s examples were excellent, and the team now follows a structured approach with confidence.